The Ultimate Guide To Injection Mold

Wiki Article

Rumored Buzz on Injection Mold

Table of ContentsThings about Injection MoldWhat Does Injection Mold Do?The Greatest Guide To Injection MoldSome Known Facts About Injection Mold.The Single Strategy To Use For Injection MoldHow Injection Mold can Save You Time, Stress, and Money.

Celebrity Rapid is completely accredited to the high quality monitoring system of ISO 13485 for clinical tools. When you're all set to start your next medical product, call us for a free layout for making evaluation and quotation - Injection Mold. We can guarantee you utilize the best materials and also the ideal process that ideal fits your medical tool requirements.Before ejection from the mold, shot formed parts are cooled off from manufacturing temperature levels to ensure that they hold their shape when expelled. During the part cooling step of the molding process, modifications in pressure, speed and plastic thickness should be decreased to prevent issues. Few facets are much more essential throughout this period than wall density.

Selecting the correct wall density for your component can have drastic results on the cost as well as manufacturing speed of production. While there are no wall thickness constraints, the goal is typically to pick the thinnest wall possible. Thinner wall surfaces use less material which lowers cost as well as take much less time to cool, decreasing cycle time.

Some Of Injection Mold

Density transitions ought to be made progressively, like 3 to 1. This gradual shift stays clear of stress concentrations as well as sudden air conditioning distinctions.

4 Simple Techniques For Injection Mold

When it involves making your components, you have a major decision to make. Should you make your parts utilizing plastic injection molding or aluminum die casting!.?.!? To aid you decide, allow's consider the significant benefits as well as drawbacks of each. The process of making a part is basically the very same whether you are making use of pass away casting or injection molding.You then liquify the product and also utilize extreme stress to inject it into the die/mold. You after that cool the die/mold with internal air conditioning lines and pass away spray on the die dental caries. You open the die and also eliminate the shot. There are some variants in technique, the significant difference in between die casting and also injection molding is that pass away casting utilizes some kind of steel, commonly an aluminum alloy, as the raw product, while injection molding makes use of plastic or polymers.

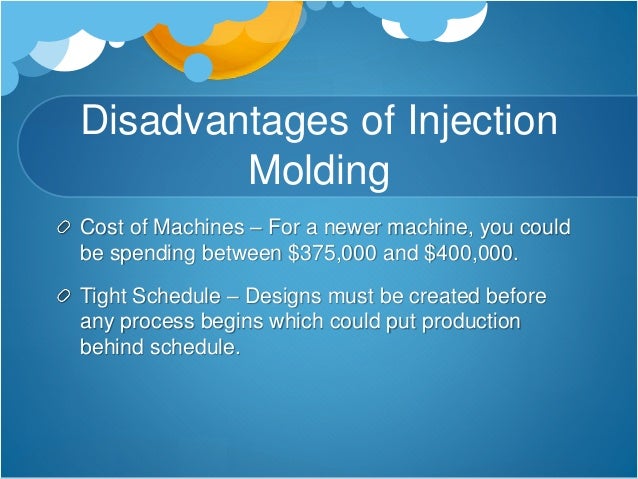

If you understand what type of parts you intend to wind up with, you know immediately which to utilize. If you're not certain which product is better that site for you as well as your firm's products, read on. Manufacturing is quicker as a result of more versatility in the molding procedure Plastic Shot mold and mildews can accommodate different plastic or polymer products Fillers can be made use of in plastic mold and mildews to increase stamina Effective procedure with really accurate finishes Effective process with a high level of precision No demand for second operations Complex styles can be much more conveniently cast Creates higher-quality items with far better tolerance that will last much longer So why would you select injection molding over die spreading? If you are aiming to generate a lot of parts very inexpensively, injection molding could be the way to go, as labor and material costs are fairly light, although it is very important to bear in mind that the price of the plastic shot molding makers themselves and also any type of additional devices can be relatively costly.

Unknown Facts About Injection Mold

Even if you are creating simpler parts, lots of people like the obvious feeling of longevity as well as top quality you enter a solid steel component over a plastic part. When you have actually decided that aluminum pass away spreading is the way to opt for all your part manufacture requires, the following action is to get in touch with Premier Engineered Products.We are a family-owned, U.S.-based firm that does every one of our die casting in our innovative die spreading plant and also have made top quality components for sectors varying from firearms to telecommunications to medical gadgets as well as a lot more. Firms that recognize die casting telephone call Premier Engineered Products. At Premier Engineered Products, we are committed to helping you offer a much better item to your consumers by supplying you terrific solution as well as excellent high quality every single time you position an order with us.

To figure out just how we can place our state-of-the-art metalworking makers as well as competence to benefit you now, just call us online today.

Not known Factual Statements About Injection Mold

At Abtec Inc., we're pleased to provide custom mold and mildew making services, aiding clients bring their product visions to life. Flexible as well as dependable, plastic shot molding is made use of to develop a big series of everyday items. Among the most prominent techniques for mass creating plastic parts, this strategy remains to climb in popularity across diverse markets and also applications.Since durations in between cycles can be as short as 15 secs, even more components can be made suggesting thousands of precision components can be created per hr, depending upon the certain mold and mildew. This high production result rate helps business increase revenue as well as revenue margins. Customized plastic injection molding permits for wonderful style flexibility.

005 inch. Having a complete understanding of clients' requirements is vital for guaranteeing proper product kind as well as feature. With years of market experience and also a devotion to shut customer collaboration, check my site our team has Visit Your URL the ability to figure out the optimal style and also material for customers' jobs, and can begin job swiftly on models (Injection Mold).

The Greatest Guide To Injection Mold

Product selection is an essential action in the manufacturing process, as well as should be based upon the desired strength of the end product. Various other vital elements to keep in mind consist of appearance qualities, such as shade and also finish, and any type of applicable governing requirements. Loads of material options are available to satisfy details application needs.

Report this wiki page